PINK ALUMINUM OXIDE BLASTING CARBIDE BLADE

|  |  |

| High Chromium | Medium Chromium | Low Chromium |

Pink aluminum oxide (Low Chromium)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 | ≥98.5 | 0.2-0.45 | ≤0.3 | 0.01-0.05 |

| F90 F100 F120 F150 | ≥98.5 | 0.2-0.45 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥98.0 | 0.2-0.45 | ≤0.40 | 0.01-0.05 |

Pink aluminum oxide (Medium Chromium)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 | ≥98.2 | 0.45-1.00 | ≤0.30 | 0.01-0.05 |

| F90 F100 F120 F150 | ≥98.2 | 0.45-1.00 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥97.8 | 0.45-1.00 | ≤0.40 | 0.01-0.05 |

Pink aluminum oxide (High Chrominum)

| Size | Al2O3 | Cr2O3 | Na2O | Fe2O3 |

| F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 | ≥97.4 | 1.00-2.00 | ≤0.30 | 0.01-0.05 |

| F90 F100 F120 F150 | ≥97.0 | 1.00-2.00 | ≤0.35 | 0.01-0.05 |

| F180 F220 | ≥96.5 | 1.00-2.00 | ≤0.40 | 0.01-0.05 |

PHYSICAL PROPERTIES(TYPICAL)

| Basic minerals | α-Al2O3 |

| Crystal size μm | 600-2000 |

| True density g/cm3 | ≥3.90 |

| Bulk density g/ cm3 | 1.40-1.91 |

| Knoop hardness kg/mm2 | 2200-2300 |

PARTICLE SIZE DISTRIBUTION

| F12 | +2800um | 0 | +2000um | ≤20% | +1700um | ≥45% | +1700+1400um | ≥70% | -1180um | ≤3% |

| F14 | +2360um | 0 | +1700um | ≤20% | +1400um | ≥45% | +1400+1180um | ≥70% | -1000um | ≤3% |

| F16 | +2000um | 0 | +1400um | ≤20% | +1180um | ≥45% | +1180+1000um | ≥70% | -850um | ≤3% |

| F20 | +1700um | 0 | +1180um | ≤20% | +1000um | ≥45% | +1000+850um | ≥70% | -710um | ≤3% |

| F22 | +1400um | 0 | +1000um | ≤20% | +850um | ≥45% | +850+710um | ≥70% | -600um | ≤3% |

| F24 | +1180um | 0 | +850um | ≤25% | +710um | ≥45% | +710+600um | ≥65% | -500um | ≤3% |

| F30 | +1000um | 0 | +710um | ≤25% | +600um | ≥45% | +600+500um | ≥65% | -425um | ≤3% |

| F36 | +850um | 0 | +600um | ≤25% | +500um | ≥45% | +500+425um | ≥65% | -355um | ≤3% |

| F46 | +600um | 0 | +425um | ≤30% | +355um | ≥40% | 355+300um | ≥65% | -250um | ≤3% |

| F54 | +500um | 0 | +355um | ≤30% | +300um | ≥40% | +300+250um | ≥65% | -212um | ≤3% |

| F60 | +425um | 0 | +300um | ≤30% | +250um | ≥40% | 250+212um | ≥65% | -180um | ≤3% |

| F70 | +355um | 0 | +250um | ≤25% | +212um | ≥40% | +212+180um | ≥65% | -150um | ≤3% |

| F80 | +300um | 0 | +212um | ≤25% | +180um | ≥40% | +180+150um | ≥65% | -125um | ≤3% |

| F90 | +250um | 0 | +180um | ≤20% | +150um | ≥40% | +150+125um | ≥65% | -106um | ≤3% |

| F100 | +212um | 0 | +150um | ≤20% | +125um | ≥40% | +125+106um | ≥65% | -75um | ≤3% |

| F120 | +180um | 0 | +125um | ≤20% | ≥40% | ≥40% | +106+90um | ≥65% | -63um | ≤3% |

| F150 | +150um | 0 | +106um | ≤15% | +75um | ≥40% | +75+63um | ≥65% | -45um | ≤3% |

| F180 | +125um | 0 | +90um | ≤15% | +75um | * | +75+63um | ≥40% | -53um | * |

| F220 | +106um | 0 | +75um | ≤15% | +63um | * | +63+53um | ≥40% | -45um | * |

MAIN APPLICATIONS

—Pink aluminum oxide is used for precision grinding of measuring tool,lathe main shafts,instruments and apparatus parts,threading work pieces and many other applications in grinding like flute grinding,tooth grinding,dry grinding of blade segments,tool and internal grinding and mounted point.

—Pink aluminum oxide is best suitable for high alloy steel applications, ideal for tool sharpening such as high speed steel cutters,reamers,chisels,end mill and sharpening band saw blades.

—Pink aluminum oxide is also recommended for knife-sharpening applications,working non-ferrous metals and the alloys.

—Pink aluminum oxide has good performance for vitrified bonded abrasives,vitrified grinding wheels,coated abrasives and blasting abrasives,

—Pink aluminum oxide can also be used for softer materials, such as wood,Synthetics etc.

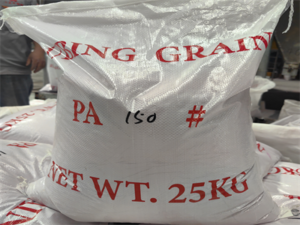

PACKAGING

|  |  |  |  |

| 25KGS PVC BAGS | 25KGS PVC BAGS+1MT BIG BAG | 1MT big bag | 1MT big bag +pallet | 25kgs pvc bags+pallet |

PRODUCTION WAREHOUSE

|  |  |  |