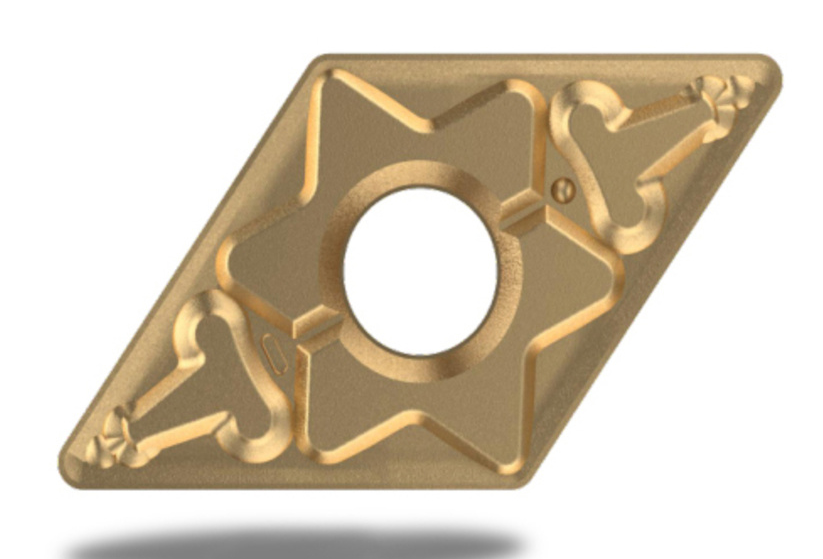

How to sandblast carbide blade?

Cemented carbide is an alloy material made of carbides with high hardness and melting point and metal binders through powder metallurgy process.Carbide blade is made of cemented carbide,then it has the properties of high hardness ( 69-81HRC at normal temperature and still can be 60HRC at 1000℃) and wear resistance.Meanwhile cemented carbide own excellent chemical stability and corrosion resistance.

Because blasting can deal with the surface roughening ,edge passivation cleaning and improve the bonding strength between the coating and the substrate.

Besides, blasting includes dry sandblasting and wet sandblasting,but because dry sandblasting is easy to bring dust pollution,then wet sandblasting is used more widely

Wet sandblasting is a method in which abrasives (usually white fused alumina,brown fused alumina and pink fused alumina)mixed with liquid is sprayed out by a sandblasting gun through compressed air.abrasive impacts the workpiece at a certain speed and angle within a certain distance to achieve the processing purpose.

About how to choose abrasives,white fused alumina,brown fused alumina and pink fused alumina ,which is the best,need consider many factors,but according the experience,mostly use pink fused alumina and sizes are F150 F180 F220